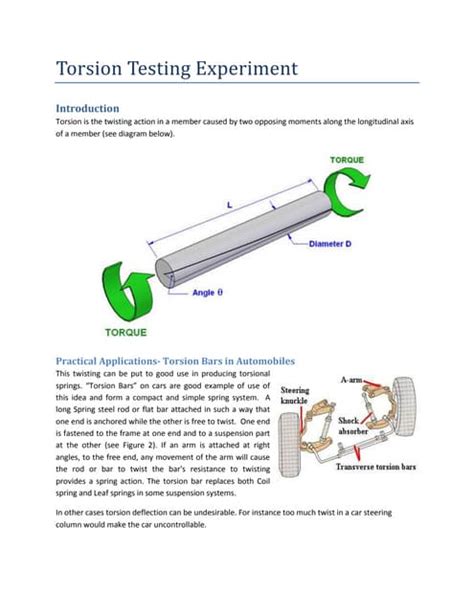

torsion test fractures|torsion test experiment 2 pdf : discount store During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is used to measure various mechanical properties of materials, including their modulus of rigidity, shear stress, and .

Serviço Premium – Site de namoro exclusivamente internaci.

{plog:ftitle_list}

WEB17 de fev. de 2023 · O Fortaleza enfrenta o CSA na quarta rodada da Copa do Nordeste 2023, neste domingo, 17, às 21 horas, no estádio Presidente Vargas (CE). Acompanhe .

Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, .In this experiment, solid cylindrical specimen of steel or brass will be subjected to a torsional load. The test will be conducted until failure (i. it will end in the fracture). During the test, the angle .

Fig. 1 shows the different types of torsion fractures and their codes used to classify them in laboratory torsion tests. The three types of fractures typically result from delamination.Types of torsion testing vary from product to product but can usually be classified as: i. Axial-Torsion: Applying both axial (tension or compression) and torsional forces to the test specimen.Torsion Testing of Structural Metals Standards • ASTM E143: Shear Modulus at Room Temperature Purpose • To determine the shear modulus of structural metals Equipment • .

During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is used to measure various mechanical properties of materials, including their modulus of rigidity, shear stress, and . As structural components fail due to fracture or excessive deformation, the primary goal of this study is to determine how a test sample reacts when twisted and subjected to . Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and .

Background and Objectives. Understanding how materials react to an applied load is essential for engineers to design structures that are both safe and effective. While there are many different .Torsion Only: Applying only torsional loads to the test specimen. Axial-Torsion: Applying both axial (tension or compression) and torsional forces to the test specimen. Failure Testing: Twisting the product, component, or specimen until .One of the most common examples of torsion in engineering design is the power generated by transmission shafts. We can quickly understand how twist generates power just by doing a simple dimensional analysis.Power is measured in the unit of Watts [W], and 1 W = 1 N m s-1.At the outset of this section, we noted that torque was a twisting couple, which means that it has .

In the shear test, as in the bending test, the stress is not uniform over the cross section. The same remarks concerning the effect of nonuniformity of stresses on the determination of material properties made in the bending test are also applied in the torsion test. The shear stress τ f at fracture is obtained from

torsion test experiment 2 pdf

Double Torsion (DT) is a powerful testing technique for fracture mechanics characterisation of brittle materials as, in principle, it provides a crack length independent test configuration.Statics - Twisting Moments. Twisting moments, or torques, are forces acting through distances (“lever arms”) so as to pro- mote rotation. The simple example is that of using a wrench to tighten a nut on a bolt as shown in Figure 6: if the bolt, wrench, and force are all perpendicular to one another, the moment is just the force F times the length l of the wrench: \(T = F \cdot l\).Static Axial-Torsion Test: Involves applying constant axial and torsional loads to measure properties like strength, stiffness, and ductility. Dynamic Axial-Torsion Test: . FRACTURE TEST. Fracture toughness is a material's ability to resist crack propagation. This property is vital for assessing a material's suitability for applications where . To perform Torsion Test on. Mild steel specimen; Cast iron specimen; . Fracture in torsion for ductile materials generally occur in the plane of maximum shear stress perpendicular to the axis of bar where as for the brittle material failure occurs along 45° hilux to the axis of bar due to tensile stress across that plane.

The SCG of different materials has been widely studied, and the theoretical and experimental conditions have been optimized. The double-torsion (DT) technique is a commonly used method to study the SCG and dynamic fracture of materials, including rocks 17, ceramics 18, graphite 19, and various single crystals 20.Nara et al. 21 observed SCG in regime 2 for .m) or foot-pound force (ft

the fracture would be in shear (longitudinal, splitting) and for a brittle material, the fracture (also called helical fracture) would be tensile (45° splitting). Equipment This experiment is performed using The SM1001 30Nm Torsion Testing Machine shown in the figure below. Figure 2: SM1001 30Nm Torsion Testing Machine

It can be seen that the flat fracture occurs after the torsion test without delamination. In the wire drawing process for high carbon steel wire, many mechanisms have been proposed to explain the . The fracture toughness, KI-V curves and subcritical growth index of five types of rocks were obtained by the double-torsion (DT) technique. Subcritical fracture propagation exists in the rock as . A torsion test twists the mild steel rod by attaching one end to the machine and applying a moment to the other end, causing the sample to spin around its axis. . Inclusion initiated fracture under cyclic torsion very high cycle fatigue at different load ratios. Int. J. Fatigue, 122 (2019), pp. 199-207.The document discusses torsion testing and the different types of failures that can occur. It explains that there are two types of torsion failures: 1) ductile failure due to shear stresses and 2) brittle failure due to tensile stresses. An image shows examples of brittle and ductile fracture surfaces from a driveshaft and brass rod tested under torsion. The document also notes that .

To address this problem, pinch-torsion test [24], [25] was developed in which the torsion component is combined with compression loading of LIB indentation test. This triggers ISCr at a lower load with smaller short spot size. The SOC of LIB under pinch-torsion test is directly related to the maximum resistive force which the LIB can withstand. The purpose of this in vitro study was to investigate fracture strength using a torsion test at the implant-abutment interface in order to assess the effect of torsion force on the connection. Methods. Thirty titanium screw implants of five different diameters (3.3, 3.8, 4.3, 5.0, and 6.0 mm) with tube-in-tube implant-abutment connections .A non-intrusive approach based on GFEM has also been proposed in [45] to analyze 3D fracture problems. Cohesive fractures have been studied in K. Kim et al. and in G. Ferté et al. [46, 47] for 3D . Background Fractured connections between implants and implant abutments or abutment screws are frequently encountered in a clinical setting. The purpose of this study was to investigate fracture strength using a torsion test at the interface between the implant and the abutment. Methods Thirty screw-type implant with diameters of 3.3, 3.8, 4.3, 5.0, and 6.0 mm .

In the torsion test, the delamination fracture was observed in the WD drawn wire for the 10th pass while it did not occur for the 12th pass NCD. In addition, the ultimate tensile strength (UTS) of .Bone fracture or break is the result of stress on the bone. Fracture can result from a variety of reasons, but the most common types include traumatic fracture, insufficiency fracture, and stress fracture. Traumatic fractures are the most common and result from accidental causes (e.g., severe fall, motor vehicle accident) or non-accidental or intentional causes (i.e., abuse). .

After the load-relaxation test, the load was applied on the double-torsion specimen at a rapid displacement rate of 5 mm/min (0.08 mm/s) to satisfy the displacement rate that required more than 0.07 mm/s for the CDR test until the specimen failed.DOI: 10.1016/j.engfracmech.2021.107903 Corpus ID: 237696937; Effect of thermal treatment on the fracture toughness and subcritical crack growth of granite in double-torsion test @article{Li2021EffectOT, title={Effect of thermal treatment on the fracture toughness and subcritical crack growth of granite in double-torsion test}, author={Diyuan Li and Jinyin Ma .test specimen and calculating the slope of the shear stress versus shear strain curve. In addition, the torsion test specimen will be twisted to failure in order to determine the shear stress at the limit of proportionality. The shear stress at the limit of proportionality is the largest value of the During the torsion test the polymers showed a linear elastic behavior until the yield point had been reached. Then, the viscoplasticity took place. Several models, based on thermodynamics with internal variables, can be used to predict the thermo-mechanical behavior of polymers under service conditions.

grips, the test shall be considered invalid and shall be repeated. 7.5 Where the fracture in the torsion test is required to be characterized, it should be done on the basis of Annex C. NOTE For wires of smaller diameter or characteristic dimension it may not be possible to .This lab report summarizes an experiment to determine the shear modulus of mild steel samples under torsion. Cylindrical mild steel specimens were subjected to increasing torque loads, and the angle of twist was measured. By plotting torque versus angle of twist, the shear modulus could be calculated from the slope. The experiment aimed to find properties like shear stress, shear .

Abstract. A new fracture toughness test, the edge crack torsion method, has been developed for characterizing the mode III delamination behavior of composites. The test is based on a laminate specimen subjected to torsion to propagate an edge delamination crack in its midplane. The crack growth mode of the specimen has been deduced to be mode III from .

torsion test examples pdf

Loterias | CAIXA

torsion test fractures|torsion test experiment 2 pdf